Nyob rau hauv cov txheej txheem ntawm stamping thiab ua hlau pwm, qhov tshwm sim ntawm cov tsis zoo stamping yuav tsum tau soj ntsuam kom meej thiab zoo countermeasures yuav tsum tau coj.

Qhov ua rau thiab kev tiv thaiv ntawm cov khoom tsis xws luag hauv kev tsim khoom raug tshuaj xyuas raws li hauv qab no, rau kev siv cov neeg ua haujlwm kho pwm:

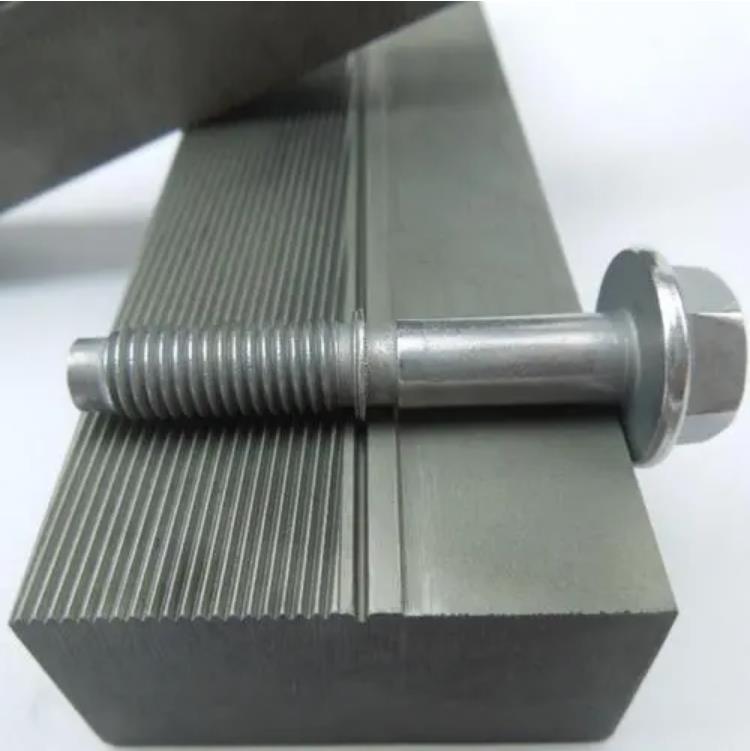

1. Burrs ntawm stampings.

(1) Yog vim li cas: ntug riam yog hnav tawm. b. Yog tias qhov sib txawv loj heev, cov nyhuv yuav tsis pom tseeb tom qab sharpening riam yam tsis tau txiav ntoo los ntawm kev yuam kev. c. Chip ntug. d. Qhov kev tshem tawm txav nce thiab nqis tsis tsim nyog lossis dhau los ua xoob. e. Cov pwm yog misaligned nce thiab nqis. .

(2) Kev tiv thaiv: a. Tshawb nrhiav kev siv thev naus laus zis. b. Tswj kev ua haujlwm raug ntawm cov pwm hlau lossis hloov kho qhov kev tsim tawm. C. Kev cob qhia riam ntug. d. Kho qhov sib txawv blanking kom paub meej tias qhov hnav ntawm lub qhov template los yog kev ua tiav ntawm cov khoom tsim. e. Hloov cov ntawv qhia pwm lossis rov ua cov pwm. .

2. Crumble thiab crush.

(1) Yog vim li cas: Qhov sib txawv ntawm ib qho loj heev. b. Tsis tsim nyog shipping nqi. c. Punching roj poob ceev heev, roj sticks. d. Cov pwm tsis demagnetize. e. Cov punch yog hnav, thiab cov chips yog nyem thiab txuas rau lub punch. f. Lub punch yog luv dhau thiab qhov ntev ntawm qhov ntxig tsis txaus. g. Cov khoom siv yog ib qho nyuaj, thiab cov punching zoo yog yooj yim. h. Kev ntsuas kub ceev. .

(2) Kev tiv thaiv: a. Tswj lub machining raug ntawm cov hlau pwm los yog hloov cov qauv clearance. b. Thaum cov pwm raug xa mus rau txoj haujlwm tsim nyog, nws yuav tsum tau kho thiab ntxuav kom huv si raws sijhawm. c. Tswj tus naj npawb ntawm cov roj twj tso kua mis, los yog hloov cov roj hom kom txo cov viscosity. d. Nws yuav tsum tau demagnetized tom qab kev cob qhia (ntau dua yuav tsum tau them nyiaj thaum xuas nrig ntaus cov ntaub ntawv hlau). e. Kawm txog ntug ntawm lub punch. f. Kho qhov ntev ntawm lub punch hniav rau hauv qhov tuag. g. Hloov cov khoom siv, hloov cov qauv tsim. Lub punch hniav nkag mus rau hauv lub ntsej muag kawg, ejects los yog kho nrog ib tug bevel los yog arc (saib cov kev taw qhia). Txo qhov kev sib txuas ntawm qhov kawg ntawm lub ntsej muag ntawm lub punch hniav thiab cov chips. h. Txo qhov ntse ntawm qhov tuag-txiav ntug, txo cov nqi ntawm kev cob qhia ntawm qhov tuag-txiav ntug, ua kom cov roughness (txheej) ntawm txoj kab ncaj nraim ntawm qhov tuag-txiav, thiab siv lub tshuab nqus tsev nqus cov khoom pov tseg. Txo cov punching ceev thiab qeeb nti dhia. .

3. Lub nti yog thaiv.

(1) Ua rau: Ib lub qhov xau me me dhau. b. Lub qhov dej xau loj dhau lawm, thiab cov khib nyiab yob dhau. c. Lub riam ntug yog hnav thiab cov burrs loj. d. Punching roj poob nrawm heev, roj nplaum. e. Qhov saum npoo ntawm cov hniav ncaj ntawm lub concave tuag yog ntxhib, thiab cov hmoov chips yog sintered thiab txuas rau cov hniav. f. Cov khoom yog mos. g. Kev ntsuas kub ceev. .

(2) Kev tiv thaiv: a. Hloov lub qhov dej tawm. b. Hloov lub qhov dej ntws. c. Ntug ntawm cov hniav yog kho. d. Tswj tus nqi ntawm cov roj dripping thiab hloov hom roj. e. Kev kho deg, polishing, them sai sai rau txo qhov roughness thaum ua. Hloov cov khoom siv, hloov qhov khoob khoob khoob. g. Kho txoj kab nqes lossis arc ntawm lub ntsej muag kawg ntawm lub ntsej muag ntawm lub ntsej muag (ua tib zoo saib rau cov kev taw qhia), thiab tshuab cua mus rau lub qhov khoob ntawm lub phaj rov qab nrog lub tshuab nqus tsev. .

4. Qhov loj me ntawm qhov sib txawv ntawm blanking.

(1) Yog vim li cas: ntug ntawm cov pwm hlau yog hnav thiab burrs yog generated (cov duab loj dhau lawm thiab lub puab lub qhov me dhau). b. Tus tsim loj thiab clearance yog tsis tsim nyog, thiab machining raug yog tsis zoo. c. Muaj qhov sib txawv ntawm cov punch thiab cov pwm ntxig ntawm cov khoom siv qis, thiab qhov sib txawv tsis sib xws. d. Daim ntawv qhia tus pin yog hnav thiab txoj kab uas hla ntawm tus taw qhia tus pin tsis txaus. e. Tus taw qhia pas nrig yog hnav. f. Qhov kev pub mis tsis tau hloov kho kom zoo, thiab lub feeder yog nias xoob. g. Kev kho tsis raug ntawm pwm clamping qhov siab. h. Lub xovxwm-hauv txoj hauj lwm ntawm qhov tso tawm yog hnav, thiab tsis muaj xovxwm-hauv (yuav tsum nias-hauv) muaj nuj nqi (cov khoom raug rub dhau los ua rau me me punch). Kuv unloaded cov hniav nias tob heev thiab lub punch yog loj heev. j. Kev hloov pauv ntawm cov khoom siv hluav taws xob ntawm cov khoom siv stamping (tsis ruaj khov thiab elongation). k. Thaum xuas nrig ntaus, lub punching quab yuam rub ntawm cov khoom, ua rau muaj kev hloov pauv. .

(2) Kev tiv thaiv: a. Tshawb nrhiav kev siv thev naus laus zis. b. Hloov kho tus tsim thiab tswj cov machining raug. c. Kho nws txoj hauj lwm raug thiab blanking qhov sib txawv. d. Hloov tus taw qhia tus pin. e. Hloov daim ntawv qhia thiab lub tes tsho qhia. f. Kho lub feeder. g. Kho cov pwm clamping qhov siab. h. Sib tsoo los yog hloov lub unloading insert, ua kom lub zog siab muaj nuj nqi, thiab kho cov khoom nias. i. Txo qhov tob tob. j. Hloov cov ntaub ntawv raw thiab tswj cov khoom zoo. k. Lub ntsej muag kawg ntawm cov hniav xuas nrig yog txiav rau hauv ib qho bevel lossis arc (cuam tshuam cov kev taw qhia) txhawm rau txhim kho kev ntxhov siab thaum xuas nrig ntaus. Nyob qhov twg tso cai, lub unloading caij yog nyob rau ntawm lub unloading hniav nrog kev taw qhia muaj nuj nqi. .

5. Cov khoom siv daim npav.

(1) Yog vim li cas: a. Kev hloov tsis raug ntawm qhov kev pub mis, thiab lub feeder yog nias thiab loosened. b. Pub ncua deb hloov thaum lub sij hawm tsim khoom. C. Lub tshuab xa khoom yog faulty. d. Cov khoom yog khoov, qhov dav tshaj qhov kam rau ua ntau yam, thiab cov burrs loj. e. Lub stamping ntawm qhov tuag tsis zoo li qub, ua rau thawj khoov. f. Tsis txaus lub qhov taub ntawm cov ntaub ntawv qhia, lub Upper tuag rub cov khoom. g. Txoj haujlwm khoov lossis torn tsis tuaj yeem poob zoo. h. Kev ua haujlwm stripping ntawm cov ntaub ntawv qhia phaj tsis raug teeb tsa kom raug, thiab cov ntaub ntawv cov ntaub ntawv poob rau ntawm txoj siv. Kuv cov khoom yog thinning thiab warping thaum pub mis. j. Cov pwm tsis tau teeb tsa kom zoo, thiab muaj qhov sib txawv loj ntawm qhov verticality ntawm feeder. .

(2) Kev tiv thaiv: a. Hloov kho b. Hloov kho c. Kho thiab tswj. d. Hloov cov ntaub ntawv raw thiab tswj qhov zoo ntawm cov khoom tuaj. e. Tshem tawm thawj qhov khoov ntawm lub pluaj. f. Kawm xuas nrig ntaus, qhia qhov convex thiab concave tuag. g. Kho lub ejection caij nplooj ntoos hlav quab yuam, thiab lwm yam h. Hloov cov ntaub ntawv qhia phaj, thiab nruab cov khoom siv rov qab siv rau ntawm txoj siv. Kuv ntxiv cov ntaub ntawv xovxwm sab saud thiab qis dua ntawm lub feeder thiab pwm, thiab ua kom muaj kev nyab xeeb hloov ntawm cov khoom siv sab saud thiab qis dua. j. Reinstall lub pwm.

Post lub sij hawm: Jan-13-2023